Multi Shuttle Box Transformation Mechanism Of GA615 Loom

When GA615 multi shuttle weaving machine is used to weave various colored fabrics, if different colors, yarn counts, and raw materials of weft yarns are used simultaneously, it is necessary to use shuttles equipped with different weft yarns. According to the arrangement requirements of the weft yarns, they are automatically sent to the working surface level with the shuttle board in sequence for shuttle feeding and weft insertion. The process of introducing different weft yarns without stopping the machine through shuttle box transformation is called multi shuttle box weaving, which is completed by a multi shuttle box transformation mechanism. The multi shuttle box changing mechanism can automatically change the color weft, but after the weft is used up, it needs to be manually replenished by stopping the machine, which brings inconvenience to continuous production.

一、Types of multi shuttle box transformation mechanisms

There are many types of multi shuttle box transformation mechanisms. As for the lifting type multi shuttle box mechanism, there are two types based on the configuration position and number of shuttle boxes.

I.Double sided multi shuttle box mechanism: This device is equipped with the same number of shuttle boxes on both sides of the reed seat, or double shuttle boxes, or four shuttle boxes, respectively represented by 2X2 and 4X4. The weft yarn can be changed in odd or even numbers. The mechanism for controlling the lifting motion of the shuttle boxes on both sides is installed on one side of the loom.

The double-sided lifting multi shuttle box transformation mechanism can be divided into the following two types based on the lifting relationship between the two shuttle boxes:

(1)Double sided multi shuttle box mechanism with simultaneous lifting and lowering: In this form, both shuttle boxes are lifted and lowered simultaneously, and the limit for the number of shuttles used is the total number of shuttle boxes on one shuttle seat. This multi shuttle box changing mechanism is always relative to the left and right shuttle boxes at the same shuttle position, and they rise or fall simultaneously.

(2)Different lifting type double-sided multi shuttle box mechanism: In this form, both sides of the shuttle box can be lifted and lowered freely, and the limit of the number of shuttles used is the total number of shuttle boxes on both sides.

2.Single side multi shuttle box lifting mechanism: This multi shuttle box mechanism is installed on one side of the GA615 loom reed seat, and the other side is a fixed single shuttle box. There are usually two types of single-sided two shuttle boxes and single-sided four shuttle boxes, represented by 1X2 and 1X4. The number of shuttles used in this form is the same as the total number of shuttle boxes on the changing side, and the number of consecutive weft insertions for each type of weft yarn is definitely even.

II.Requirements for GA615 Multi Shuttle Box Transformation Mechanism

To improve the yield and quality of colored fabrics and achieve smooth operation, there are certain requirements for the multi shuttle box changing mechanism:

1.Compared with the same width automatic shuttle loom, the multi shuttle box loom has a lower speed. In order to maximize the speed, the entire structure should be simple, the movement should be light and agile, and the vibration should be small.

2.To ensure accurate lifting and stable positioning of the shuttle box, the clearance between each connecting transmission component should be small, and the rods should have sufficient rigidity. The height error between the working surface (shuttle box bottom plate) and the shuttle board after the shuttle box lifting transformation shall not exceed the required standard.

3.The institution should be equipped with a steel plate saving device suitable for weaving large cycle color grid fabrics, in order to simplify the steel plate arrangement program and save the number of steel plates used.

4.The functions of each device need to be closely coordinated with the opening and shuttle feeding movements to ensure the normal operation of the mechanism.

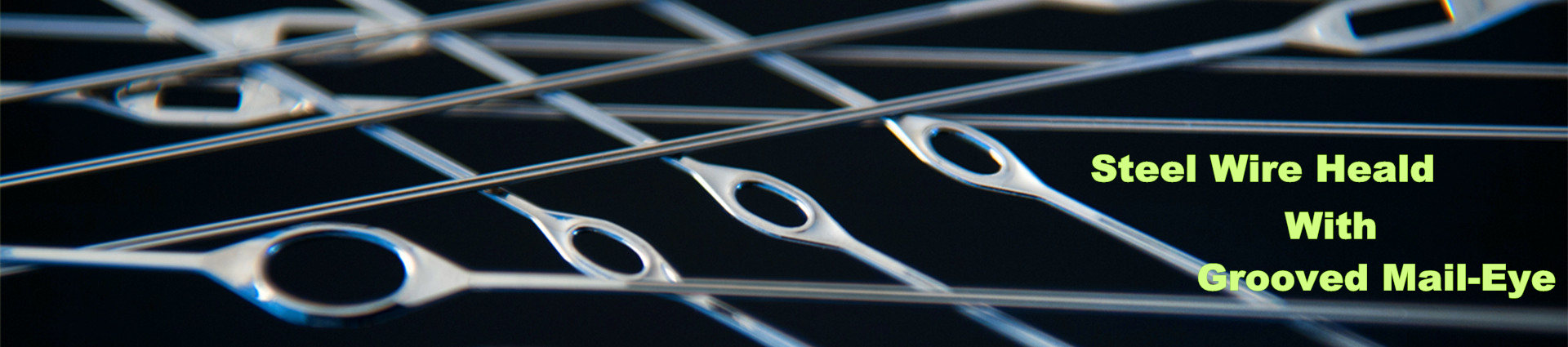

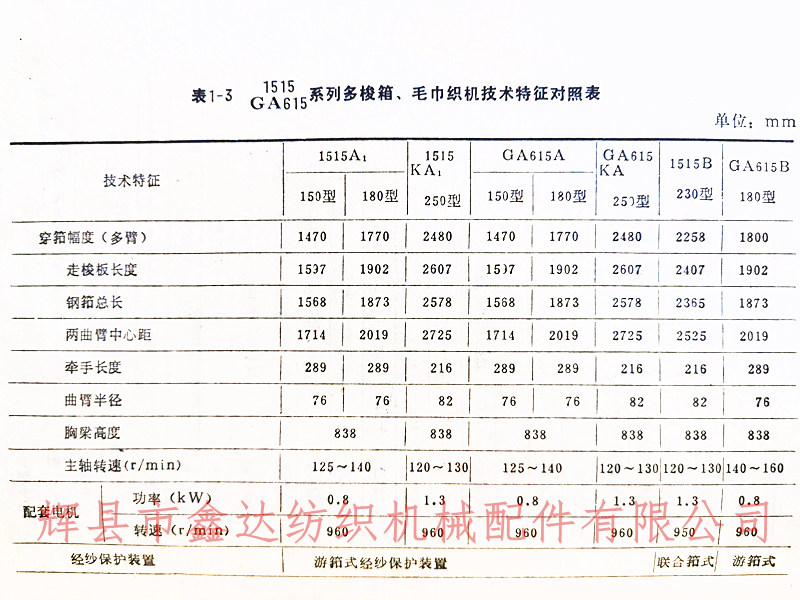

III. The form of wide width series multi shuttle box weaving machine

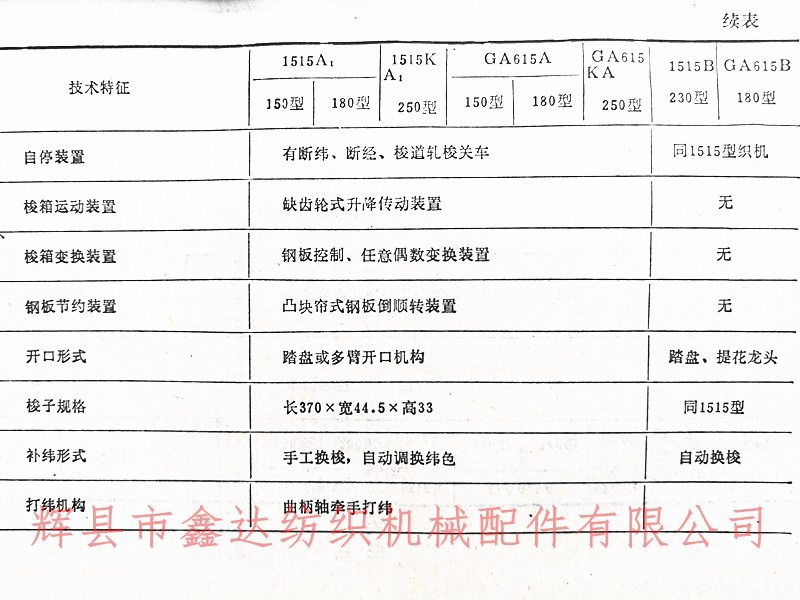

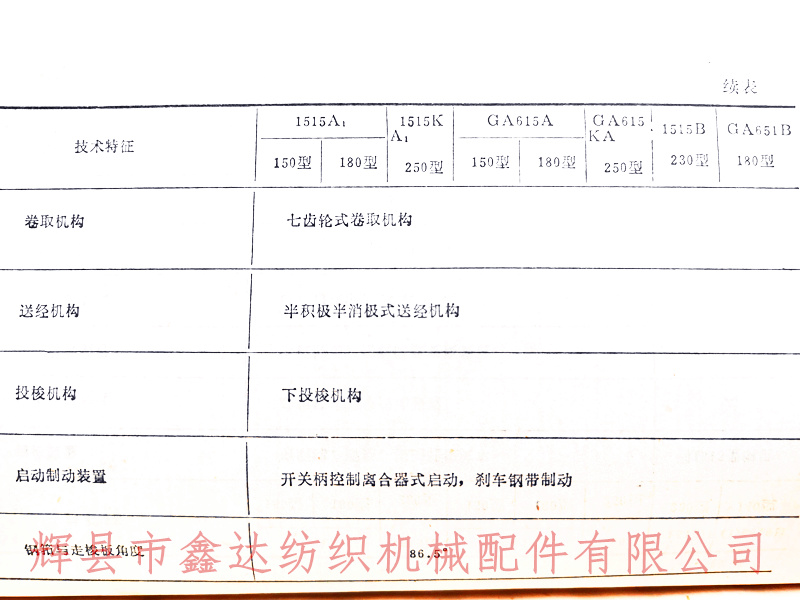

The 1515 and GA615 series multi shuttle box weaving machines are both in the form of single-sided 1X4, which can be configured with 4-color circulation and even weft insertion. The types, models, specifications, and technical features of this type of multi shuttle box loom are shown in Table 1-3. The shuttle box lifting and changing mechanism of this type of multi shuttle box loom is equipped with a shuttle box lifting device, a shuttle box changing device, and a steel plate saving device. Some other models of multi shuttle boxes are also equipped with stop feeding and stop winding devices.