Calculation Formula For Weft Density Of 1511 And 1515 Weaving Machines

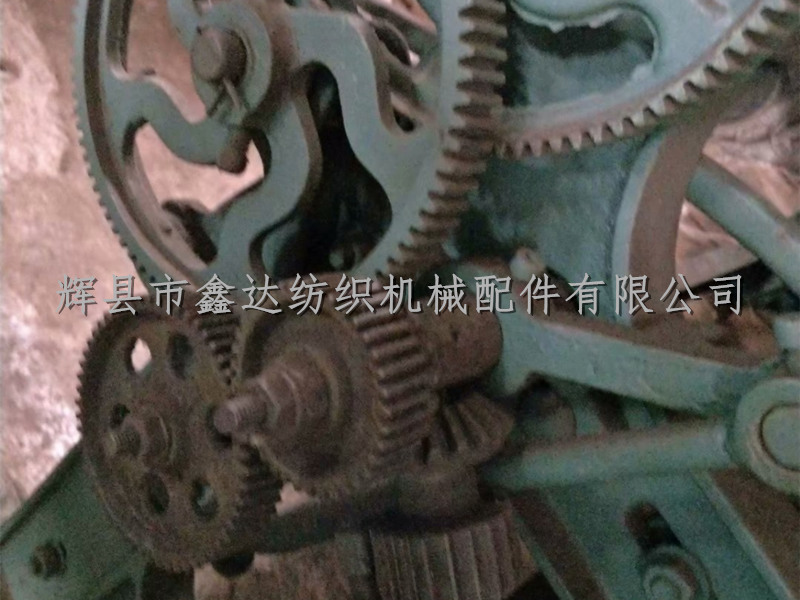

The calculation formula for warp density of 1511 and 1515 weaving machines provides a detailed introduction to the conversion relationship of warp density of weaving machines, involving the number of teeth for winding multiple gears and the diameter of the bristle roller. It is designed based on the L7 saw gear with one tooth per rotation.

The calculation formula for the weft density of 1511 and 1515 looms is as follows:

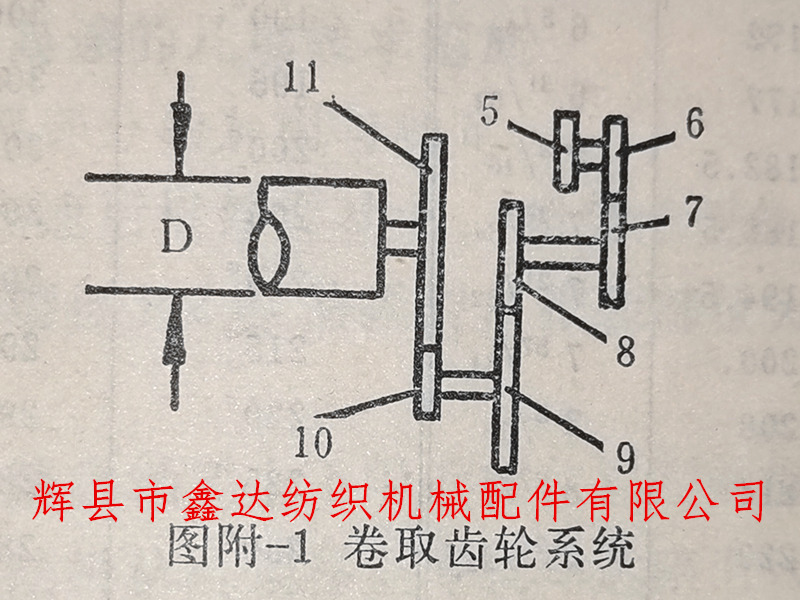

The theoretical weft density P2 of the fabric can be calculated using the wheel system shown in Figure Attachment-1

Z5*Z7*Z9*Z11

Pw=────────────────

m*Z6*Z8*Z10*πD

In the formula; Pw - Theoretical weft density of weaving machine;

Z5- saw gear (L7=24 teeth);

Z6- Standard gear (L33 teeth density);

Z7- Variable gear (L33 teeth density);

Z8- Roll up small gear (L00-4 core small gear with 24 teeth);

Z9- Large intermediate wheel (L10 bridge gear=89 teeth);

Z10- Small intermediate wheel (L11 bridge small gear=15 teeth);

Z11- Roll up the bristle roller gear (L13 bristle roller gear 96 teeth);

D - Diameter of the hair winding roller (12.83 cm);

M - The number of teeth per rotation of the saw gear (1 tooth).

If the values of the diameters of the gears and the carding rollers in the winding mechanism system of the 1511 loom are included in the equation, then:

24×89x 96 Change the number of gear teeth

Pw=——————————— X ————————————————

1x3.14×12.83× 24×15 Standard gear teeth count

Change the number of gear teeth

=14.13×—————————————————

Standard gear teeth count

If the longitudinal shrinkage rate e generated after the fabric is taken off the machine is considered to be 3% (the shrinkage rate varies depending on the fabric variety, generally 3% for khaki, poplin, labor fabric, yarn dyed checkered fabric, etc., and 2% for fine fabric, twill fabric, and warp fabric), and the actual weft density of the fabric per 10 centimeters needs to be calculated, the following formula can be used:

14.13 Change the number of gear teeth

P'w=———— X 10 X —————————————————

1-3% Standard gear teeth count

Change the number of gear teeth

=145.67× ——————————————————

Standard gear teeth count

The commonly used standard gear is 37 teeth. When weaving a 23 × 21 flat fabric, changing the gear to 63 teeth will result in a weft density of every 10 centimeters P'w is;

P'w= 145. 67 x (63÷37)=248 PCS

Figure Attachment-1: Coiling Gear System

If there are other requirements for latitude density, gear tooth count, and standard gear tooth count, they can be calculated according to the above formula.